Benefits of Progressive Design-Build

Progressive design-build (PDB) is a delivery model that allows water utility owners to develop their capital projects faster, in alignment with their goals while benefiting from risk reduction and cost guarantees.

Through PDB, owners benefit from a simplified procurement process with a shorter timeline than traditional design-bid-build (DBB) delivery, early price certainty and collaboration with the design-builder at the beginning of the design process.

Progressive Design-Build Tackles Water Utilities’ Top Concerns for Capital Projects

Primary concerns from water/wastewater utilities include:

- Cost escalation, scope creep, outsized contingencies and change orders

- Protracted schedule, missed milestones and late project delivery

- Retained risk, designer/contractor performance and settling disputes

- Involvement in key steps of the design process and critical decisions

10 Benefits of Progressive Design-Build

Below is a list of 10 PDB benefits showing how this delivery method can resolve owners’ primary concerns while bringing additional benefits to critical water infrastructure needs.

1. Reduced Owner Risk with Allocation to the Design-Builder

The single most significant benefit of Progressive Design-Build for owners may be their ability to allocate appropriate risks to the design-builder without inflating project costs. Final risk allocation is negotiated as part of Phase 1 with the guaranteed maximum price (GMP) proposal. The owner, in conjunction with the PDB team, decides the party best equipped to manage each risk. This reduces the owner’s exposure to risks related to delays, cost overruns and design errors.

2. Cost Certainty and Transparent Pricing

Progressive Design-Build pricing development, in step with the design development and risk mitigation, is transparent and open-book, eliminating the unknown contingency costs inherent to a fixed-price design-build (DB) model.

The PDB price model has several benefits to owners:

- The cost estimate is developed gradually throughout design, producing a GMP in alignment with the owner’s budget.

- PDB enables early procurement of long-lead items as the design progresses to mitigate cost volatility of goods and avert supply chain issues.

- The owner can request a price for each technical alternative before committing to one preferred alternative; this is not available with fixed-price DB.

- PDB delivery provides an early warning if the estimated cost is at risk of exceeding the budget, enabling the design-builder and owner to course correct early, including with value engineering, to help get the project back in line with the budget.

Stay up to date

Get Kiewit’s water news directly to your inbox.

Subscribe to Get Kiewit Water Insights

3. Shortened Schedule and Streamlined Project Execution

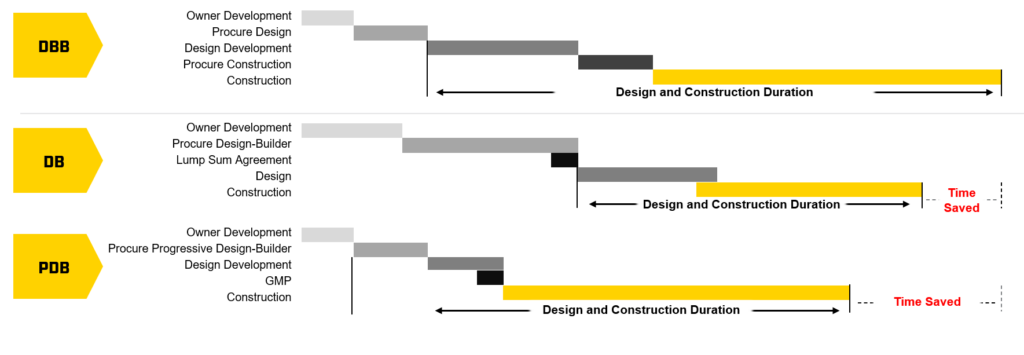

Figure 1: Time Saved with PDB vs. DBB delivery

Progressive Design-Build’s integration of design and construction enhances the efficiencies of project execution and reduces communication gaps that have traditionally led to budget overruns and schedule delays. PDB enables early work packages, a phased approach and concurrent activities that streamline the schedule.

4. Collaborative Value Engineering

Value engineering (VE) aims to reduce project costs and schedule while achieving the owner’s goals and maintaining quality. In Progressive Design-Build, VE is proactive and highly collaborative as it integrates the expertise of all stakeholders. This contributes to a more tailored finished project that meets both the functional and aesthetic expectations of the owner and community.

Collaborative VE fosters practical innovation and creative solutions that frequently result in cost-effective enhancements beyond the owner’s initial concept. PDB also provides an early warning when the estimated cost is in danger of exceeding the established budget, enabling the initiation of VE in Phase 1 to recover the budget.

5. Contracting with the Most Qualified Firm

With traditional DBB, contractors with the lowest bid price are selected, but they sometimes recoup the cost of their low bid with change orders that can result in an adversarial relationship with the owner. When “most qualified” enters the discussion, the idea is that this is the firm best positioned to minimize the risk to the project and maximize VE for the project. With DB, both qualifications and the price are factored into the selection.

Progressive Design-Build enables value-based selection, which is based on the firm’s ability to deliver the project at the lowest risk/cost. PDB enables owners to hire the most qualified firm without being influenced by bid price; this can result in innovation and collaboratively developed project enhancements, capital and maintenance cost savings, and a reduced schedule. Owners are in control of securing the best overall value for the lifecycle of their projects.

6. Owner Makes Key Design Decisions

Owners are actively involved throughout the project by providing continuous input, refining their vision and making informed decisions. After the design-builder presents a cost/benefit analysis based on real-time prices, the owner has the data to make the best decisions about each design aspect and alternative. The PDB process has built-in flexibility for the owner, enabling changes to be made more easily during the design phase and facilitating adaptation to evolving needs and unforeseen challenges.

Sign up for Kiewit Water News

Get Kiewit’s water news directly to your inbox.

Subscribe to Get Kiewit Water Insights

7. Single Point of Contact and Accountability from Concept to Startup

Progressive Design-Build is an ideal solution that can give the owner a single point of contact from initial concept through design, construction, commissioning and startup. This simplifies project management and accountability, reducing the potential for conflicts. As the project develops, the design-builder takes full accountability for performance, cost and schedule. PDB also reduces the administrative burden for owners as they deal with a single entity for both design and construction, which can streamline decision-making and communication.

8. Seamless Communication and Ability to Accommodate Adjustments Without Disruption

Progressive Design-Build facilitates the earliest collaboration between the owner, operations and maintenance staff, and the design-build team. The owner’s input is encouraged and valued, fostering mutual trust and alignment on project goals. Early involvement of the construction team allows a seamless transition from design to construction, which reduces project timelines. Builders have a better understanding of design intent, leading to a smoother construction process and a higher-quality end product. Early collaboration with the same team from start to finish brings seamless communications and the perspectives of the designer, builder and owner; it allows for greater input.

The feedback loop between the owner, designer and contractor facilitates adaption to changing project conditions and the ability to accommodate adjustments without major disruptions. This ultimately leads to an outcome closely aligned with the owner’s expectations.

9. Reduced Commitment Through Simplified Two-Phase Procurement Process

Progressive Design-Build reduces the time and cost of procurement for owners with its simplified two-phase procurement and delivery process. This two-phase approach gives the owner optimum controls throughout with the ability to “off-ramp” at the end of Phase 1 if they do not agree with the GMP and proposal.

Phase 1 – Preconstruction:

In Phase 1, the owner selects a design-builder based on qualifications and past performance. In this preconstruction phase, the design-builder collaborates with the owner to define the scope of work, lead permitting, funding, preliminary design, constructability reviews, value engineering, and startup and commissioning planning.

The PDB design process includes periodic “progressive” estimates the owner approves as the design advances. This progression enables early identification of risks, circumvents scope creep and keeps costs within the owner’s budget. When the design is 50% – 75% complete, the design-builder presents the owner with a GMP proposal for final design, construction, commissioning and startup. The owner has the option to require 100% design with the GMP proposal.

Phase 2 – Construction, Commissioning, and Startup:

After the owner accepts the design and cost proposal, they enter a Phase 2 contract with the design-builder for final design (if not completed in Phase 1), construction and startup.

10. Flexibility for Owner to Make Changes

The owner has the flexibility to off-ramp at the end of Phase 1 if an agreement is not reached on the GMP and proposal. In the case of taking the off-ramp, the owner can instead bid out Phase 2 construction to select a different contractor under DBB procurement. However, off-ramping is unlikely because the “progressive” design process includes periodic estimates as the design detail advances, and this enables incremental owner decisions/approvals and early identification/mitigation of scope creep to reduce the potential of an agreement on GMP not being reached.

More Water Utilities Are Seeing the Value of Progressive Design-Build

Progressive Design-Build delivery is gaining in popularity with water utilities across the U.S. Although collaborative delivery is not allowed in some regions or states, some utility owners have had success securing authorization to use one or more methods.

PDB can benefit medium- and large-sized capital projects and can be just as beneficial for smaller projects. This delivery model is especially advantageous for complex, high-risk projects that require innovative solutions and projects with an accelerated schedule, for example when an owner is facing a consent decree with a hard deadline.

Take a look at how Progressive Design-Build has seen success on several different projects, including on two projects in California as well as another in Arizona.

Learn more about Kiewit’s water infrastructure capabilities