Process and Manufacturing

Process and Manufacturing

Kiewit provides comprehensive project delivery services for process and manufacturing, including early involvement, feasibility studies, design, procurement, construction, construction management and commissioning. Our experience ranges from new facilities, expansions and renovations to maintenance and shutdowns. We recognize that each client’s project has unique goals and requirements. By engaging our construction and engineering teams early, we support the development of customized solutions that bring our client’s visions to life.

Markets We Serve

Biomanufacturing

Drawing from our experience in food and beverage manufacturing, we bring a unique perspective to biomanufacturing by creating efficient, adaptable facilities in an evolving market. With deep expertise and a commitment to speed-to-market, we stand out among our peers.

Specialty Chemicals

The complexities of specialty chemical projects require a partner with the experience and resources to meet demands. Our extensive experience in managing process-driven and chemical projects, along with our capabilities as an EPC contractor, establishes us as a reliable partner for our clients.

Battery Manufacturing

The future of the battery manufacturing industry is growing at an amazing pace, driven by the global shift towards electric vehicles (EVs), renewable energy storage and portable electronic devices. Kiewit has positioned itself to become a leader in this industry.

G3 Terminal Vancouver

NORTH VANCOUVER, BRITISH COLUMBIA | PROGRESSIVE DESIGN-BUILD

Our project team engineered, procured, constructed and commissioned (EPC) a grain export terminal on Canada’s west coast to optimize receiving, storage and shipping. Our commitment to addressing safety, construction and procurement challenges early on led to the project being completed on time and within budget. Early involvement enabled us to identify a geotechnical plan reconfiguration, saving $24 million and preventing future issues.

By the Numbers

#2

Top Contractor

ENR, 2024

#3

Top Design-Build Firm

ENR, 2024

290+

Process and Manufacturing projects

since 1970

10x

BETTER SAFETY PERFORMANCE

than the Industry Average

140+

year track record

with Food & Beverage Manufacturing

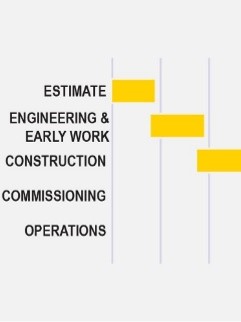

Project Delivery: Feasibility to Final Engineering

Our project delivery approach includes FEL-1 (identification and feasibility), FEL-2 (preliminary design) and FEL-3 (FEED)

through detailed design and into construction and commissioning.

IDENTIFICATION

& FEASIBILITY

& FEASIBILITY

PRELIMINARY

DESIGN

DESIGN

DEFINITION /

FEED

FEED

DETAILED

DESIGN

DESIGN

FEL (front-end loading), FEED (front-end engineering design)

Providing Reliable Solutions in Process and Manufacturing

FULL-PROJECT DELIVERY

As both a self-performing designer and constructor, Kiewit’s processes collaboratively engage project development, engineering, procurement, construction and commissioning teams to create an integrated approach that provides greater outcome certainty.

FEED-to-EPC CONVERSION

With constructability in mind at every step of project development, we progress projects from the conceptual design phase through FEED and into EPC, mitigating the risk of delays and escalating construction costs.

Progressive design-build

We unite our clients with our design-build team early in the project life-cycle to clearly define each project phase’s scope, schedule and budget, ensuring precise and timely project completion.

Outcome certainty

Our engineering-led, construction-driven team fosters scope and schedule alignment, resulting in early risk identification and greater predictability. Kiewit’s participation in front-end engineering design and ECI often results in a more accurate final cost and schedule.